ADDING FUEL

Updated May 17, 2001

There are many ways to add

fuel to an engine. Some are covered here.

How do you know if you need more fuel? Get an

inexpensive A/F gauge of good accuracy from DawesDevices

Darren is *not making*any more at

the moment, but will pick up production as soon as he's finished improving the

build-time to better keep up with future orders.

Hey, man! You

don't need any extra fuel... you're running rich enough

already!!

But if you *DO* need extra

fuel...1.

Raising the fuel pressure:

Raising the

pressure is good for only small increases in HP. Item

1is good for people who are happy with their present boost level,

and merely want to drop their EGT's a little, or add an extra light on the A/F

gauge. It is not for people looking to add lots of boost.

Since we start with a fairly high stock pressure (55 psi over boost), we're

already at 75 psi at 20#'s of boost. You need a very good pump and immaculate

fuel filter to go much beyond 75 psi. It's not good for the injectors to see much more pressure than that, either.

If you're looking for a *tiny*bit more fuel,

you can raise the pressure to 60 or 65. MAKE SURE that you're still 60 or 65 psi

over boost pressure at WOT and high boost. You need a fuel pressure gauge that

you can see from the driver's seat.

You can raise your fuel pressure by squeezing the regulator "can"

with the spring in it. That tightens the spring, and raises the fuel

pressure.

On OLDER REGULATORS WITH THE HOSE

BARB FITTINGS,

you have to make a little jig to hold the reg in place as you squeeze

it in a vise. The fuel hose fitting must be protected, and the reg must be

held by the flange that runs around it's center.

you have to make a little jig to hold the reg in place as you squeeze

it in a vise. The fuel hose fitting must be protected, and the reg must be

held by the flange that runs around it's center.

Find a short piece of exhaust tubing or water pipe that just

slides over the body of the reg. You'll have to cut a slot in the pipe to clear

the fuel line fitting that sticks out sideways.

Once the slot is in the pipe's side, slide the pipe over the reg

body until it butts up against the flange in the center of the reg. The pipe

should be just long enough to protect the fuel line fitting (hose barb) that

sticks out of the bottom of the reg.

To protect the little vacuum line nipple

that sticks out of the opposite end, use a chromed socket from your socket set.

Slip it over the nipple, and center it on the reg. Selecta socket that'll push

down on the can just outside of the center recess where the nipple comes out of

the reg.

To protect the little vacuum line nipple

that sticks out of the opposite end, use a chromed socket from your socket set.

Slip it over the nipple, and center it on the reg. Selecta socket that'll push

down on the can just outside of the center recess where the nipple comes out of

the reg.

Now take the

entire assembly of the pipe, the reg, and the chromed socket, and place it snug

in the vise jaws. Keep that socket centered!

Now take the

entire assembly of the pipe, the reg, and the chromed socket, and place it snug

in the vise jaws. Keep that socket centered!

Close the vise approximately 1/8", and your pressure will jump up

about 10 psi.

Close the vise approximately 1/8", and your pressure will jump up

about 10 psi.

On NEWER REGULATORS WITH O-ring

fittings, instead of hose barbs, like on my '89's, You can just use sockets on

both sides of the reg, and don't have to make the home made pipe / jig.

If you want to set your new

pressure exactly, hook a rubber tube from a pressurized air tank to the side fuel

fitting that's sticking out of your homemade pipe/jig, add a gauge to the line

with a tee, and SLOWLY crack open the air tank valve. You want it

barely cracked open, otherwise you'll let the pressure out of the

tank too fast, and get a false reading. The pressure will rise to a

point, then begin leaking out of the reg, and will rise no more. You'll hear the

air hissing out, and the pressure will stay at the same point. That point should

be 55 psi before you squeeze the reg in the vise.

Each turn of the vise will raise the pressure right in front of

your eyes, and you can stop anywhere you'd like.

Each turn of the vise will raise the pressure right in front of

your eyes, and you can stop anywhere you'd like.

Make sure that you've got high pressure in the air tank; it has to

be OVER whatever pressure you're shooting for. Don't go too far squeezing,

because you can't back up!

60 psi will make

your injectors flow 4.5%more fuel. 65 psi will give you almost 9% more fuel. 70

psi gives almost13% more fuel. You've got to have a STRONG fuel pump (Walbro

Viper pump, or similar) to maintain 70 psi over boost, but any stock pump should

handle60-65 psi over boost.

An alternative to the vise is to

stand the assembly on a hard surface, and tap the top chromed socket with a

hammer. Don't go wild with the hammer!

Remember that injectors can be

damaged by pressures more than 75 psi over boost, and that you must have a good

enough pump & filter to keep the pressure high under WOT. Having 65 psi over

boost at 5 lbs of boost is no good if you have only50 psi over boost at 20 lbs

of boost. The pump's got to be healthy enough to STAY at 65 over boost at all

boost levels. A clean filter is a must.

Just check your fuel pressure at WOT, under boost, to see if

the pressure remains the same amount over boost.

2. Larger injectors with reduced fuel

pressure:

Now we enter an

area where there's room to raise the boost a LOT! If you install injectors that

are way too large for your motor, like 42pph or 52pph injectors on a stock

computer, you can drop the fuel pressure to make them flow just a little more

than stockers.

You can lower your fuel pressure by making your present regulator

adjustable with an inexpensive conversion. The conversions are now

offered at a good price. You send James a healthy stock regulator, and you

get back an adjustable unit.

Try JamesRichardson, of Canada.

Price is in the $55 area.

He does

excellent work.

Remember, you

just send him a healthy regulator, and you do no work; it comes back ready to

rock and roll.

| Fuel pressure |

45 PSI |

40 PSI |

35 PSI |

30 PSI |

| Flow of 52 pph "+40% injectors" |

47 pph |

44 pph |

42 pph |

38 pph |

| Flow of 42 pph "+20% injectors" |

38 pph |

36 pph |

34 pph |

31 pph |

Example#1: Let's say that you have 27

pph T1 injectors, and you want to upgrade for big power in the future. You

can run42 pph (+20% injectors) units at 30 psi, and they'll act like 31 pph

injectors.

When you raise the

fuel pressure to just 35 psi, with your pump still *loafing*, you'll have the

flow ofT2 injectors.

Example

#2: You have stock 33 pph T11 injectors, and you swap

for +20% injectors. Run 40psi fuel pressure, and they flow like 36 pph

units. Roughly 10% over normal, which is easy for your computer to idle

clean & smooth.

Example#3: You have stock

33 pph T11 injectors, and you swap for +40% injectors. Run 30 psi, and you get

38pph injectors, which is a big improvement over stock.. People often question

the quality of the spray pattern at 27 psi, which I run. I can only tell you that

I get good gas mileage and pass emissions with those big 52pph units running at 27

psi. Other car companies run their fuel pressures way below our stock55

psi.

In any of the above examples, you can now go to a few more pounds

of boost before leaning. When you raise boost above the "leaning" point, it's

time to raise your fuel pressure.

Of course, the hot trick is to get the fuel

pressure to rise all by itself, whenever it's needed.

3.Gettingthe pressure to rise on it's own, as you need

it.

You can

gradually close off the return line as the boost rises with an adjustable gain

regulator.

The way Slug

runs is with an adjustable gain regulator.

CARTECH is selling this adjustable gain regulator for $209, plus shipping.

This model is number 20002. It is fully adjustable from 1-7

psi of fuel pressure per pound of boost. My car

likes 3:1 gain; your car might like 2.5:1, or 4.1:1. No problem!

Remember that we're dealing with high fuel

pressures, and therefore need fuelinjection fuel hose. Normal fuel

hose is much weaker than F.I. hose.

Here's a sample of how the fuel curve works on a car running big

injectors with 30 psi fuel pressure and a 3:1rate on the rising gain

regulator:

4. Extra injectors.

My second

favorite technique, and also the cheapest, is to add extra

injectors.($20- $40 per set of junkyard injector,

new pressure switch, and "tee" with fuel line.) Pressure switches turn them on as needed, and your car runs a

totally stock fuel system when you're not at WOT, so gas mileage and emissions

are unaffected.

DarrenDawes is

selling pressure activated switches.

COLD START INJECTORS: You can

look at old VW's and Saabs in your local junkyard. On the intake manifold you'll

see that there are 4 injectors neatly in a row, and one more injector all by

itself. The lone injector is the cold start injector .Cut off the fuel line with

snips or cutters, and unbolt the two little bolts on the injector flange. It

lifts right out, with no effort.

There's a banjo fitting on the top of

these Bosch injectors. Leave it on, and leave the first couple inches of hard

skinny fuel line on the banjo fitting. You can slip 3/16ID fuel hose right over

the 2 inches of line already on the injector, and clamp it on.

To supply fuel, you'll need to get brass

fittings from NAPA to make a "tee" that has 5/16" hose barbs on each end, with a

3/16 nipple in the middle.

You splice the tee into

the rubber fuel line that feeds your fuel rail. I use 3/16" rubber

fuel line to run from the tee to the injector. You can use metal line if

it makes you feel better. Then connect the metal lines with short pieces of 3/16"

fuel line and clamps.

The cold start

injector has a nozzle that squirts out the fuel. Drill a hole into the

intercooler tubing that's just slightly larger than the nozzle, then slip a

half-inch long piece of fuel line over the nozzle.(5/16 ID) Lower the

injector nozzle into this hole, and use it's flange as a template to mark where

the 2 mounting holes will go. Then drill small holes in the intercooler tubing

where your marks were made. When you tighten the two sheetmetal screws into the

holes you drilled, the fuel line will compress and conform to the shape of the

intercooler tubing, making an air tight gasket. Now the injector is

mounted.

Years ago the NOS company did flow testing to find

the best placement for their fogger nozzles. They wanted the gasoline/air to have

time to mix well before reaching the intake valves. They found 6" before the TB

to be the best place for good dispersion.

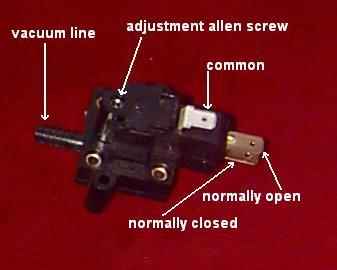

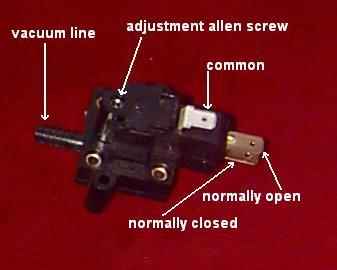

Pressure activated switch; use one to

activate your extra injector.

You

will note that there's a vacuum line barb on the switch. These switches DON'T

LIKE vacuum! Use a pressure source that doesn't see vacuum. Use an intercooler

tube; epoxy a small vacuum line barb on it.

...Or use the

intake manifold for a source, but put in a one-way (check)valve so that it

doesn't see vacuum. Then install a tiny pinhole vent to atmosphere between the

check valve and the pressure switch (about .015"to .020")

The switch will

work on higher boost

when the adjustment screw is turned clockwise; it will work at

lower boost when the

screw is turned counter-clockwise.

The polarity of the 2

injector wires doesn't matter; it'll work no matter which color wire goes to

positive. Send one wire directly to positive, and have a pressure switch send

ground to the injector at 14 psi or so.

Watch your rich-lean gauge; keep about .9V on the gauge. If you don't have one, get

one. Go to DawesDevices for a great

gauge.

Don't have it come on early

unless your rich-lean gauge tells you it's needed. (less than .9V) The extra

injector will allow a few more psi of boost. That's when you really feel the

difference.

Flow rates of these injectors

commonly support either 15 (usually the VW units) or 30 HP (usually the Saab units). Apply 12 volts to click them open, then blow through

them. The

ones that are slightly harder to blow through are good for 2 psi more boost (15

HP) The injectors that are slightly easier to blow through are good for 4 psi

more boost (30 HP) Strangely, the ones with the smaller looking

injector holes flow more, and are the "30 hp" units. These seem to be mainly in

old Saabs...

THIS INFORMATION IS GIVEN "ASIS" AND

WITHOUT WARRANTIES AS TO PERFORMANCE

OF OR ANY OTHER WARRANTIES WHETHER EXPRESSED OR IMPLIED. NO

WARRANTY OF

FITNESS FOR A

PARTICULAR PURPOSE IS OFFERED. BY USING THIS INFORMATION YOU

RELEASE THE AUTHOR FROM ANY LIABILITY

WHATSOEVER.

HOME