Boost

Controller

Updated May

14, 2002

Here is a boost controller that

incorporates quick spool up, minimal spikes, and minimal hassle. You will

merely have to clean it once in a while, or else put a tiny filter in front of it so

that dirt never reaches it. Then set it, and forget it.

"Grainger valve" is just a nick-name for a simple ball & spring check valve with

adjustable spring tension. McMaster-Carr sells them as part number:

48935K25

The above

set up is adjustable and you will get to see if you like the quick spool up. If

you do like it then you should add the simple parts below to make a 2-stage

controller. Then you go from one boost level to another with the flip of a toggle

switch.

You can follow the diagram below to have the quick

spool up, *ONLY* when you floor it. Sometimes "lazy" driving is required, and you don't want quick

spool up. A wide-open-throttle switch is even better than a toggle switch; you

only go to high boost when you floor it. It makes the "drivability" of the car

excellent! Try it; you'll like it! The Grainger valve controls the high boost

setting, while the "low" setting is permanently at minimum boost, which is

usually about 7 psi.

Please note

that the unused vacuum barb on the solenoid valve is

blocked off! I represented the block with a black rectangle.

You must cap off this nipple. Again, there is a small (about .020") vent hole drilled into

the output barb of the Grainger valve to act as a vent.

Because of several requests, below

you will see a fully manual "high-low" boost setup with adjustable "high", and

adjustable "low" settings. The bleed to adjust "low" acts as the vent.

If you're gonna run around with the low setting closed

a lot, then add a vent anyway! The

Grainger

valve controls the "high" setting.

Not all

solenoids flow the same. Some flow much more than others. Apply 12Vto one at a

time, and blow through them with your mouth. Use the ones that are easiest to blow through.

Solenoid valves cannot hold back high pressure that exceeds their

spring power; at some point pressure will leak past the closed valve. Get a

Mityvac and apply pressure to the center barb while12V is applied to it. Since

you have capped off the top barb, it shouldn't let any air through, and it should

hold a pressure equal to your highest boost setting. If you want to run 18 psi

boost, but the barb leaks at 12psi (for example), then pressure-test the OTHER

bottom barb, and whichever one holds MORE pressure is the one you want to face

the yellow restrictor in the diagram.

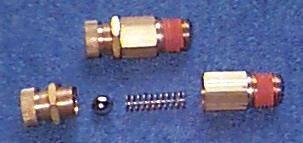

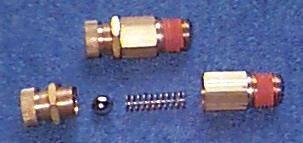

Here's how you make and adjust

it:

To

make the valve, move

the check ball to the other side of the spring.

Take it from here, and put it

THERE! Then screw on a brass barb

fitting.(McMaster Carr part number) 5346K51

Drill a tiny hole (about .020") in a brass barb first...

(90degree brass barb is part # 44555k142)

Take a bigger

stronger bit, like a .035" or .040"bit, and slip it all the way down your chuck

until it barely protrudes. Adjust it so that it's *almost*

long enough to go all the way through the brass, but not quite.

Drill with the larger bit until it bottoms out against the chuck. Now you

have

a thin brass wall left that's easy to drill

through with the little .020" bit.

Then bang the barb into the hole with a hammer. It should

be in there really tight!

Then assemble the whole thing, and the finished product

looks like this.

The barb with the

orifice drilled in it (the 90^ barb) has to face the wastegate actuator,

and the un-drilled barb (the straight one) has to face the source of boost

(intake manifold or turbo output nipple)

To adjust the valve, unlock the

lock-nut, and screw the unit together, so that it gets shorter. The shorter you

make it, the higher the boost goes. You should be able to get it really close to

14 lbs without hitting cut out. Re-lock the lock ring, and it'll stay

where you set it.

The knurled knob turns to make

the valve body shorter or longer. The lock ring stops the movement after

adjustments are made. The vent orifice needs no filter, as it never sucks

air in. Making the valve longer LOWERS boost, while making the

valve shorter RAISES boost.

If you don't want to make your own,

DarrenDawes is

making and selling these controllers.

Here is a schematic from a factory T2 sticker that shows

one possibility of tapping into existing lines.

A late model T1 set up, like my 89's.

It has been noted that spiking seems to be minimal when

the lines are kept short, and the vent hole is kept small. Try .020" - .022" for

a vent hole.

HOME